How to install electric heater

The installation of the electric heating tube is very important. Its function is like the human heart. If we want this heart to work for a long time, we need to understand it correctly and prevent it.

Stop the operation error and let it be damaged. Therefore, we have always believed that the installation of the electric heating tube needs to follow certain steps, and follow the correct operation steps to make the electric heating tube work for a long time.

go with. So how to do it?

1. Ensure that the furnace temperature is evenly distributed. In large-scale medium-temperature furnaces and high-temperature furnaces where radiation heat transfer is the mainstay, in addition to installing components on the furnace wall and bottom, electric heating pipes can also be installed on the furnace roof and the furnace door. At the same time, more electric heating pipes should be installed in places where the heat loss of the furnace is large, near the hole of the furnace door, and near the outlet of the vibrating bottom furnace. When the furnace height is very short, the electric heating tube is often arranged on the furnace bottom and the furnace roof.

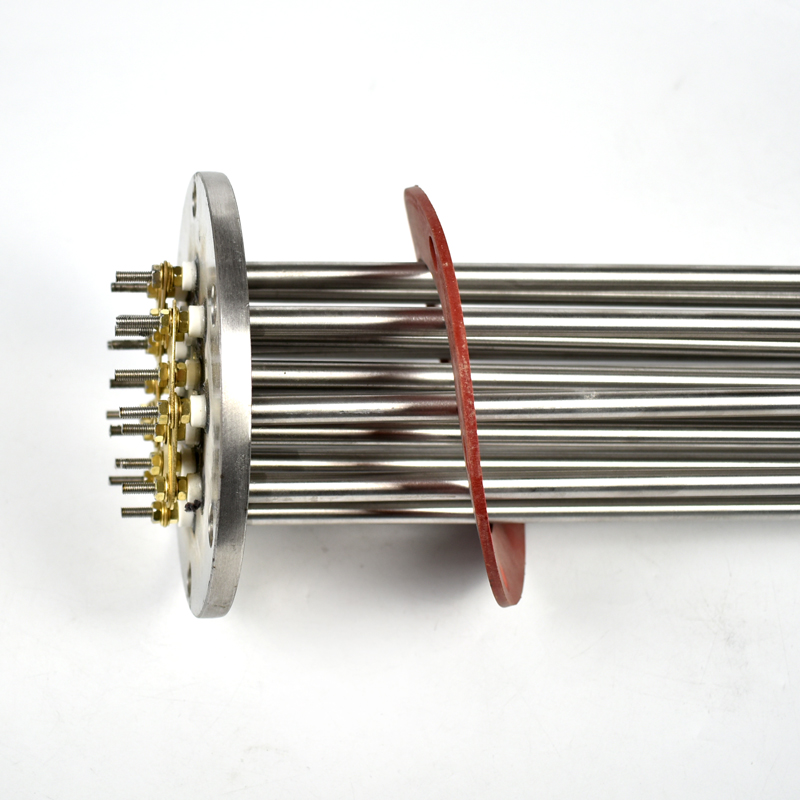

2. There are three installation methods for the corrugated type, spiral type and the corrugated type of the strip-shaped electric heating tube. From the service life, the silk-shaped corrugated type is better, and the strip-shaped corrugated type is better

However, the filamentary spiral is worse. The corrugated filament electric heating tube has better heat exchange conditions. Even if the surface load is larger, the service life is longer, so it can save electric heating tube materials and maintenance man-hours.

3. Minimize the radiation shielding between the electric heating tubes and between the supporting bricks on the furnace wall. The installation position of the electric heating tube should make it easy for heat to be transferred to the workpiece, but not only partially overheat the workpiece.

4. High-aluminum products should be selected for the support of the electric heating tube of the medium-temperature furnace. The high-temperature furnace with the furnace temperature above 1000°C should use relatively pure alumina products, and the low-temperature furnace can use general clay products. The iron oxide content in refractory products should be small, and asbestos, slag wool, water glass, etc. should not be in contact with the electric heating tube. Because these generate fusible eutectic with the electric heating tube, the element will be burnt, and the oxide film layer of the electric heating tube can be destroyed, and the electric heating tube will be damaged by accelerated oxidation.

The installation of industrial electric heating pipes in the equipment may be far more than these. How can electric heating pipes work better for a long time? We are willing to explore together. This will not only promote the improvement of our producers but also improve the quality of products.